Description

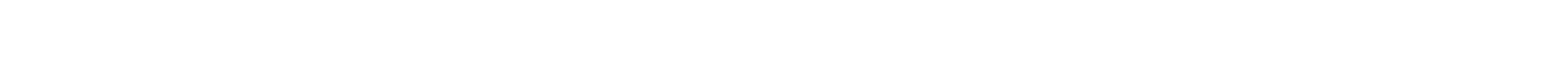

The GTC Matrix Connectors provide rugged, high-performance interconnect capability for demanding industrial, transportation, and heavy-equipment environments. Built on Amphenol Industrial Operations’ proven GT and Matrix legacy platforms, this connector series offers a durable reverse-bayonet coupling system and versatile contact configurations engineered for reliable performance under vibration, shock, moisture, and thermal extremes.

Table of Contents

Overview

The GTC Matrix power and signal connector is designed for engineers and buyers who need a versatile circular connector that can carry both high-current power and low-level signal in one durable package. With its aluminum shell construction, multiple service class options, and industry-proven reverse-bayonet coupling, the GTC Matrix family is widely used in off-road equipment, rail systems, factory automation, and a broad range of harsh industrial applications.

This connector family combines MIL-C-5015 style contact layouts with the GT Series reverse-bayonet interface, creating a hybrid design that meets modern requirements while maintaining backward compatibility with many existing system designs. The quick-mating mechanism delivers a positive, tactile lock, reducing installation time and minimizing the risk of incomplete engagement.

Key Features & Benefits

A key advantage of the GTC Matrix power and signal connector is the mechanical reliability delivered by the reverse-bayonet coupling. This locking mechanism is designed for environments with vibration, repeated connect/disconnect cycles, or exposure to dust and moisture. The self-locking lugs secure the mated halves and help prevent accidental loosening, improving equipment uptime and reducing maintenance concerns.

The rugged aluminum housings are available in multiple finishes, enabling buyers to select corrosion protection tailored to their environment. A wide selection of insert arrangements supports mixed power and signal distribution, giving OEMs flexibility when routing control circuits, sensors, and power feeds through a single connector interface.

Sealing options protect against moisture ingress, while high-quality elastomers help maintain long-term environmental protection. Additional benefits include a broad operating temperature range, crimp or solder terminations, and accessory options designed to ensure cable strain relief and mechanical stability in harsh environments.

Typical Applications

The GTC Matrix power and signal connector is used across industries requiring ruggedized, field-ready interconnects. Heavy equipment manufacturers use these connectors for engine systems, chassis wiring, hydraulic controls, and operator cab electronics where vibration and temperature extremes are common.

In rail and mass-transit environments, GTC Matrix connectors support braking systems, doors, HVAC circuits, and electrical subsystems that demand high reliability and easy serviceability. Their robust construction and locking mechanism make them ideal for equipment exposed to dirt, moisture, and mechanical stress.

In factory automation, these connectors are installed in robotics, conveyors, material-handling systems, and industrial control cabinets. Their hybrid power/signal capability helps reduce connector count, simplify routing, and streamline installation. They are also used in renewable energy equipment, industrial generators, and mission-critical power distribution systems.

Technical Details

The GTC Matrix connector series includes contact layouts based on MIL-C-5015 patterns. Power contacts support high-current requirements, while signal contacts handle low-level control circuits. Both are engineered for low resistance and long-term stability.

The reverse-bayonet coupling provides fast mating and a secure lock without torque tools. Elastomeric grommets maintain sealing performance, and insert materials provide dielectric strength under harsh conditions. Engineers can select plating and corrosion-resistant finishes suited to their specific environment.

Accessories such as caps, backshells, gaskets, and strain reliefs help complete the installation. Cable termination options include crimp or solder contacts. For related circular connector technologies, explore our GT Reverse Bayonet Series.

Resources & Support

Amphenol Industrial Operations offers complete engineering support for teams evaluating the GTC Matrix connector family. Datasheets, dimensional drawings, material specifications, and accessory recommendations are available to help simplify integration and documentation.

If custom configurations are needed — such as unique insert arrangements, special plating, or integrated cable assemblies — AIO can support application-specific builds. For standards background on environmental sealing, visit the IEC 60529 IP ratings reference.

For technical support, sample requests, or guidance selecting the right configuration, contact us to discuss your application.

Features & Benefits

Specifications

Electrical

Mechanical

Material

Environmental

Connectors to fit your industry requirements by design

TS1 Series | High Current eMobility Power Connector

Floating Mate Connector Series | Floating Blind Mate Connector

Amphe-PV H4 Plus™ Cable Connector | Solar Connector

Liquid Cooling Systems | Reliable Quick Disconnect Connectors

Connect with Our Team

Amphenol Industrial's product lines consist of rectangular, standard miniature, fiber optic, EMI/EMP filter, and a variety of special application connectors.